Call us at

+91 9830074667

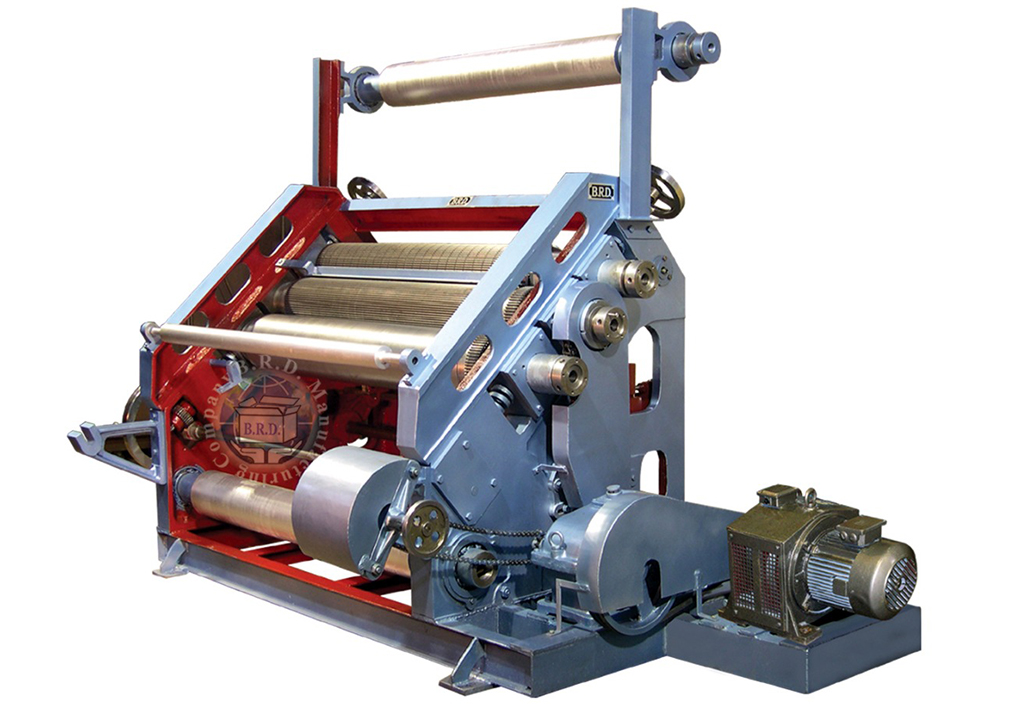

The Machine Offers High Rate of Production and Enhance Efficiency. The Flute Rollers are Mounted on Bearings for Smooth Running and Imparts Proper Impression on Paper Two Pre-Heaters are provideed for Demoisturising the Paper. "JUMBO" type Hydraulic POwer Pack Twin Shaft Mill Roll Stand with capacity of Lifting upto 1 ton Reel can be provided at an additional cost.

| Technical Specification: | |

| Design Speed SFH - 600 E | 33 mtrs. / min |

|---|---|

| Effective Width | 52" / 56" / 62" / 72" |

| Motor Reguired (H.P) | 7.5 / 7.5 / 3 and 10 / 5 (for 52" mc) |

| Heating Load (KW) | 45 (for 52" mc) |

| Corrugated Roller Dia (mm.) | 230 |

The Vertical Model is sturdy in construction and simple to operate. The rollers are bearing mounted. Electric heaters are provided for appropriate conversion of paper to 2 ply corrugated sheets. The machine is provided with manually operated twin shaft reel stand. The variable speed motor is recommended for better quality and economy in wastage at an additional cost. Normal motorised reel stand or 'JUMBO' Type Motorised reel stand can be provided at an additional cost.

| Technical Specification: | |

| Machine Size | 32" / 42" / 45" / 52" / 56" / 62" |

|---|---|

| Motor Reguired (H.P) (Manual Reel Stand) |

3 / 3 / 5 / 5 / 7.5 / 7.5 |

| Heating Load (K.W.) | 15 / 21 / 21 / 27 / 27 / 36 |

| Gross Weight (Kgs) (Manual Reel Stand) | 2200 / 2500 / 2700 / 3000 / 3200 / 3500 |

| Production Capacity (RF/PM) | 70 / 70 / 70 / 70 / 70 / 70 |

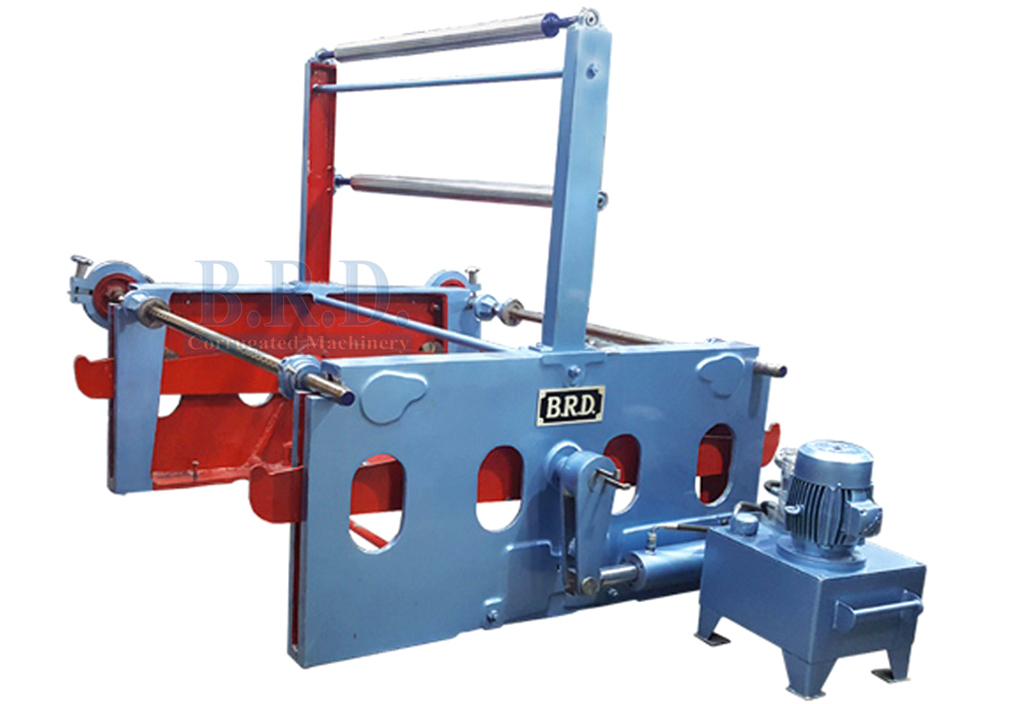

Twin Shaft Hydraulic Power Pack Self Loading Mill Roll Stand is Used for Lifting Paper Roll Regular Modeal or "JUMBO" Type Model is available as per Requirement.

| Technical Specification: | |

| Design Capacity | 1 Mtr. Dia - 800 Kgs |

|---|---|

| Effective Width | 45" / 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 2 / 2 / 2 / 3 / 3 |

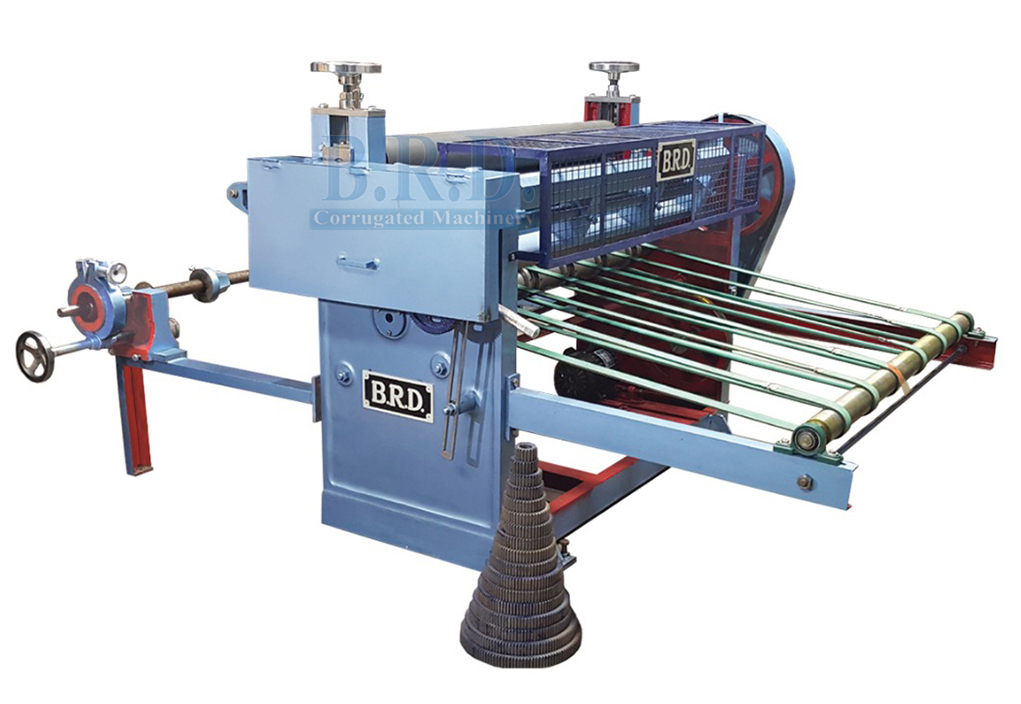

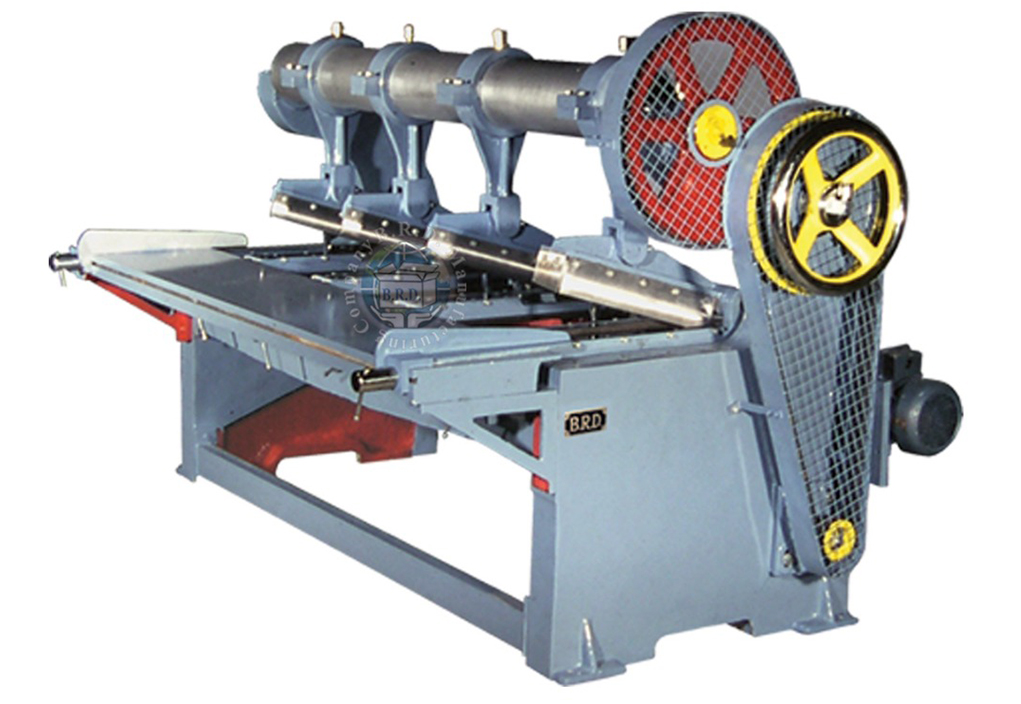

The machine is designed for high production for cutting paper as well as 2 ply corrugated sheet without damaging the flutes. This machine can be used as an independent unit or can be attached to a corrugation machine for direct and accurate sheet cutting, which minimizes the percentage of wastage. Set of Gear (PINION) is provided for cutting of sheets to the required length. A Delivery Conveyor is provided to carry the sheet out.

| Technical Specification: | |

| Design Speed | 33 mtrs. / min |

|---|---|

| Effective Width | 45" / 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 2 / 2 / 3 /3 5 |

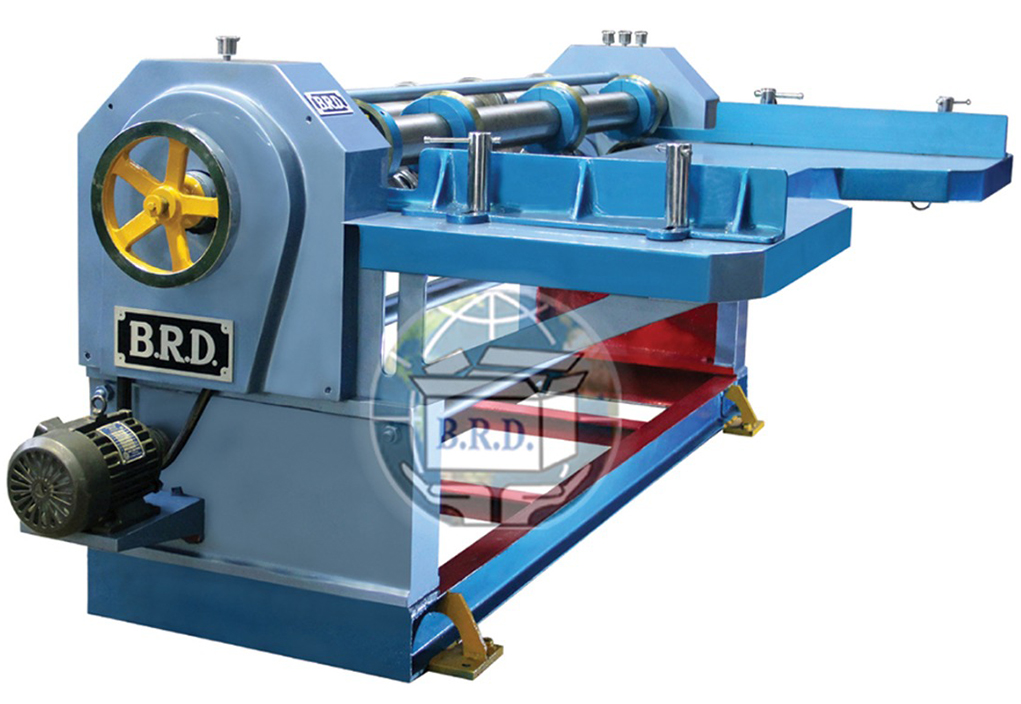

The Machine is used for Applying Glue on the Tip of the Courrugation 2 Ply Sheets to make different ply. It Consist of Three Rollers which is Smoothly Finished to ensure even Lamination of Boards. Wheels with eccentric bushes are provided to the one roller for the adjustment for optimum application of gum and one for even impression on 2 Ply Board. Hard chromed Rollers are provided for Economy and better Quality at an additional cost.

| Technical Specification: | |

| Design Speed | 5000 Stitches / min |

|---|---|

| Effective Width | 65" / 75" / 85" / 95" / 105" |

| Motor Required (H.P) | 0.5 / 0.5 / 0.5 /0.5 / 1 |

The Machine is used for cutting and creasing of corrugated boards simultaneously. The machine is study and contains graded alloy steel knives for smooth cutting. Gauges are provided for accurate cutting and creasing of sheets as per required measurement.

| Technical Specification: | |

| Machine size | 65" / 75" / 85" / 95" / 105" |

|---|---|

| Motor required (H.P.) | 1.5 / 2 / 2 / 2 / 2 |

| Floor space | 55"x85" / 55"x100" / 55"x110" / 55"x120" / 55"x130" |

| Machine height | 48" / 48" / 48" / 48" / 48" |

| Gross Weight (Kgs) | 2200 / 2600 / 2800 / 3000 / 3200 |

| Production Capacity | 5000 / 5000 / 5000 / 5000 / 5000 |

The Machine is used for slotting and corner cutting of the corrugated board simultaneously. The machine has three slotting and one corner cutting head. Gauges are provided for accurate feeding.

| Technical Specification: | |

| Machine size | 65" / 75" / 85" / 95" / 105" |

|---|---|

| Minimum space between slots | 4" / 5" / 5" / 5" / 5" |

| Maximum slot depth | 12" / 18" / 18" / 18" / 18" |

| Power required (H.P.) | 2 / 3 / 3 / 3 / 5 |

| Floor space | 55"x90" / 58"x100" / 58"x110" / 58"x120" / 58"x130" |

| Machine height | 58" / 62" / 62" / 62" / 62" |

| Gross Weight (Kgs) | 2200 / 2800 / 3000 / 3200 / 3400 |

| Production Capacity (Stroke per minute) | 30 / 30 / 30 / 30 / 30 |

The Machine is used for Creasing, Cutting, Slotting and Corner Cutting of Sheets Simultaneously. If has four sets of Creasing Heads. Three Sets of Trimming Heads, Three Slotting Heads and one Corner Cutting Head. Feeding Table Adopts Chain Style, Manual Feeding. The Slotting and Creasing Head move togather for Measurewment Set. The Slotting Blade Adopts 360° Phase Movement Controlled Electrically.

| Technical Specification: | |

| Maximum Speed | 70 Pcs/Min |

|---|---|

| Maximum Feeding Size (mm.) | 1200 x 2200 / 2400 1400 x 2200 / 2400 |

| Minimum Feeding Size (mm.) | 650 x 350 |

| Maximum Groove Depth (mm.) | 300 mm. |

| Motor Power | 4.0kw. |

| Card Board Thickness | 3 / 5 / 7 Ply (3mm. - 10mm.) |

The Heavy Duty Platen punching and embossing machine is utilised for cutting, creasing, embossing and punching of corrugated sheets. The drive and stop to the platen is transfered by an electromagnetic clutch. Two safety guides areprovided for instant stoping of the machine in emergency.

| Technical Specification: | |||||

| Machine Size | Platen Size | Impression Per / Hour | Motor H.P. Required | Floor Space | Gross Weight |

|---|---|---|---|---|---|

| 20" x 26" | 23" x 29" | 2000 | 3 H.P. | 60" x 45" | 2.7 MT. |

| 20" x 30" | 23" x 33" | 2000 | 3 H.P. | 60" x 51" | 3.0 MT. |

| 22" x 32" | 25" x 35" | 1800 | 5 H.P. | 62" x 53" | 3.5 MT. |

| 25" x 37" | 28" x 40" | 1800 | 5 H.P. | 65" x 55" | 4 MT. |

| 32" x 42" | 36" x 46" | 1500 | 7.5 H.P. | 70" x 68" | 5.5 MT. |

| 36" x 50" | 40" x 54" | 1200 | 7.5 H.P. | 77" x 75" | 7.5 MT. |

| 45" x 65" | 49" x 69" | 1000 | 10 H.P. | 86" x 92" | 10.5 MT. |