Call us at

+91 9830074667

The Machine Offers High Rate of Production and Enhance Efficiency. The Corrugated Flute Rollers, Pressure Roller and Glue Rollers are by Pneumatic adjustment. The Flute Rollers 48CrMo are Mounted on Bearings for Smooth Running and Imparts Proper Impression on Paper. TC Flute Rollers can be Provided at an Additional Cost. The Middle Flute Roller is Fitted with Vaccum Suction Jacket instead of Adapters which Keeps the Flute Profile Stable Two Pre- Heaters are Provided for Demoisturising the Paper. Gimble Drive Reduces Noise and Keeps Machine Running Stable. Shaftless Electric/Hydraulic Reel Stand can be adopted at an additional cost.

| Technical Specification: | |

| Design Speed SF - 320 S | 120 mtrs. / min |

|---|---|

| Effective Width | 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 7.5 / 7.5 / 3 (for 52" mc) |

| Steam (Kg) | 450 - 500 (for 52" mc) |

| Corrugated Roller Dia (mm.) | 320 |

The Machine Offers High Rate of Production and Enhance Efficiency. The Corrugated Flute Rollers, Pressure Roller and Glue Rollers are by Pneumatic adjustment. The Flute Rollers 48CrMo are Mounted on Bearings for Smooth Running and Imparts Proper Impression on Paper. TC Flute Rollers can be Provided at an Additional Cost. The Middle Flute Roller is Fitted with Vaccum Suction Jacket instead of Adapters which Keeps the Flute Profile Stable Two Pre- Heaters are Provided for Demoisturising the Paper. Gimble Drive Reduces Noise and Keeps Machine Running Stable. Shaftless Electric/Hydraulic Reel Stand can be adopted at an additional cost.

| Technical Specification: | |

| Design Speed SF - 280 S | 80 mtrs. / min |

|---|---|

| Effective Width | 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 7.5 / 7.5 / 3 (for 52" mc) |

| Steam (Kg) | 450 - 500 (for 52" mc) |

| Corrugated Roller Dia (mm.) | 280 |

The Machine Offers High Rate of Production and Enhance Efficiency. The Corrugated Flute Rollers, Pressure Roller and Glue Rollers are by Pneumatic adjustment. The Flute Rollers are Mounted on Bearings for Smooth Running and Imparts Proper Impression on Paper. 48 rMo Flute Rollers can be Provided at an Additional Cost. The Middle Flute Roller is Fitted with Vaccum Suction Jacket instead of Adapters which Keeps the Flute Profile Stable.Two Pre-Heaters are Provided for Demoisturising the Paper. Gear Box Drive to Reduce Noise and Keep Machine Running Stable. The Machine is Equipped with Hydraulic Power Pack Mill Roll Stand. Shaftless Electric / Hydraulic Mill Roll Stand can be adopted as an option.

| Technical Specification: | |

| Design Speed SF - 260 E | 50 mtrs. / min |

|---|---|

| Effective Width | 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 7.5 / 7.5 / 3 (for 52" mc) |

| Heating Load (KW) | 45 (for 52" mc) |

| Corrugated Roller Dia (mm.) | 260 |

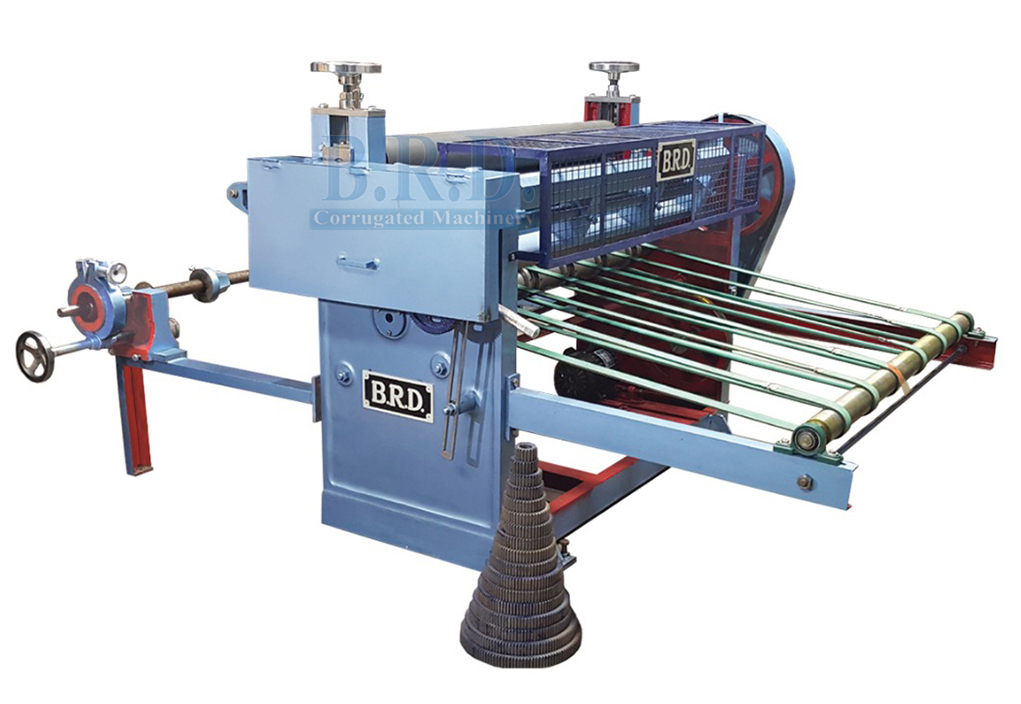

The machine is designed for high production for cutting paper as well as 2 ply corrugated sheet without damaging the flutes. This machine can be used as an independent unit or can be attached to a corrugation machine for direct and accurate sheet cutting, which minimizes the percentage of wastage. Set of Gear (PINION) is provided for cutting of sheets to the required length. A Delivery Conveyor is provided to carry the sheet out.

| Technical Specification: | |

| Design Speed | 33 mtrs. / min |

|---|---|

| Effective Width | 45" / 52" / 56" / 62" / 72" |

| Motor Required (H.P) | 2 / 2 / 3 /3 5 |

The Machine is used for Applying Glue on the Tip of the Courrugation 2 Ply Sheets to make different ply. It Consist of Three Rollers which is Smoothly Finished to ensure even Lamination of Boards. Wheels with eccentric bushes are provided to the one roller for the adjustment for optimum application of gum and one for even impression on 2 Ply Board. Hard chromed Rollers are provided for Economy and better Quality at an additional cost.

| Technical Specification: | |

| Design Speed | 5000 Stitches / min |

|---|---|

| Effective Width | 65" / 75" / 85" / 95" / 105" |

| Motor Required (H.P) | 0.5 / 0.5 / 0.5 /0.5 / 1 |

The machine is used for creasting and Slitting of Paper Board. The Thin Blade Makes the Paper Board Edge Perfect without Raw Edges, to Promote Quality and appearance of Paper Board.

| Technical Specification: | |

| Machine Width (mm.) | 2000 / 2200 / 2400 / 3000 |

|---|---|

| Motor Required (H.P) | 3Kw. |

| Production Capacity | 40 Pcs. / Min. |

The Machine is Used for Flexo Printing Creasing, Cutting and Corner Cutting of Sheets Sumultaneously It Offers High Precision of Printing with easy Operation. Opening and Closing is Controlled Electrically. Locking up and Elevating Plate is Done by Pneumatic System. Printing Roller Adopts 360° Phase Adjustment, Controlled Electrically Even During Running Machine. The Slotting and Creasing Heads move togather for Measurement Set. The Slotting Blade Adopts 360° Phase Movement Controlled Electrically. Printing Roller Adjust Laterally upto 10mm.

| Technical Specification: | |

| Maximum Speed | 60 Pcs/Min |

|---|---|

| Maximum Feeding Size(mm.) | 1200 x 2200 / 2400 1400 x 2200 / 2400 |

| Minimum Feeding Size (mm.) | 650 x 350 |

| Maximum Groove Depth (mm.) | 300 |

| Motor Power | 5.5 Kw. |

| Card Board Thickness | 3 / 5 / 7 Ply ( 3mm. - 10 mm.) |

The Machine has been Designed & Manufactured to Stitch the Card Board & Corrugated Boxes. The Machine is made of Graded casting and the perts are Standarised Interchangeable and made Alloy Steel.

| Technical Specification: | |

| Design Speed | 300 Stitches / min |

|---|---|

| Effective Width | 20" / 30" / 36" / 42" / 48" / 60" |

| Motor Required (H.P) | 0.5 /0.5 / 0.5 / 0.5 / 0.5 / 0.5 |